Vacuum Brazed Cold Plates

Liquid cooling has certain limitations on its ability to cool effectively due to the limitations of tube-bending.

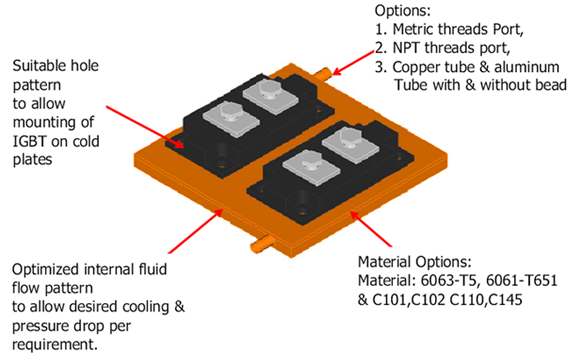

These limitations can be easily overcome by custom designed aluminum or copper cold plates.

The most commonly employed methods to generate the cooling path are through the use of folded fins, stakes of carefully machined thin fins, or precision die-forged parts. SNS Cooling has significant technical know-how and design expertise in creating leak-free plates. We highly recommend involving SNS designers during the design stage to benefit from our years of experience. This will help design a cost-effective solution to your crucial cooling requirements and a hassle-free end-product. Every custom cold plate is unique in its design, but the process and fundamentals of design remain the same. Our engineering team uses advanced thermal analysis software to model your heat loads and create a cold plate design that meets or exceeds your thermal and pressure-drop performance requirements. After the design stage, your custom cold plates are manufactured, pressure-tested to meet your requirements, and stamped “T” after testing. We can comply with lot traceability and can provide ultrasonic inspection records upon request.

Cold plates are brazed per the following AWS standards:

Copper: AWS C3.6M/C3.6 CLASS C (Class A and B on request)

Aluminum: AWS C3.7M/C3.7 CLASS C (Class A and B on request)